Seals for the world’s largest seawater desalination plant

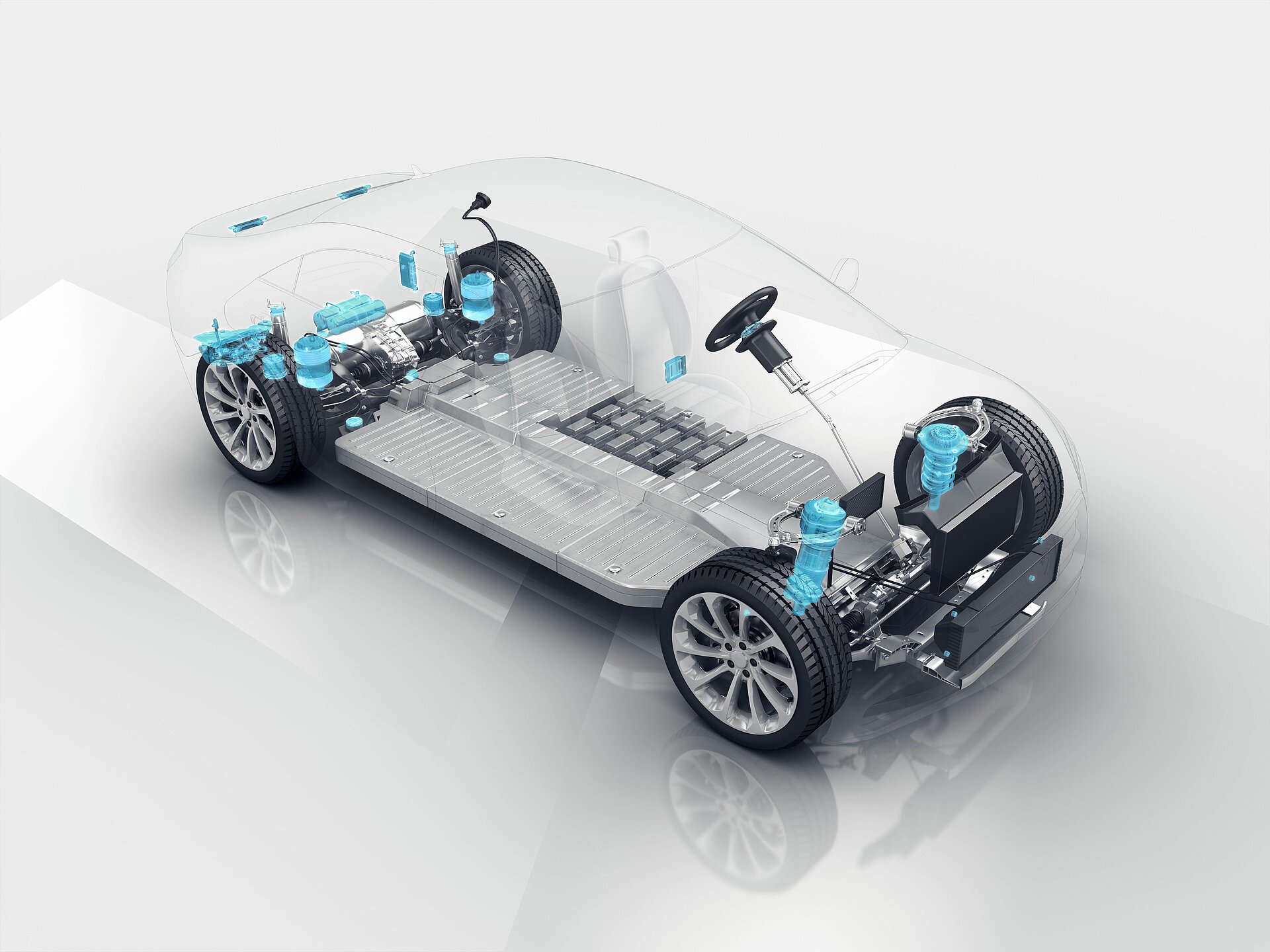

Just a few kilometers south of Tel Aviv, something big is happening. With a total investment of almost half a billion euros, the world’s largest seawater desalination plant, “Sorek II”, is under construction there.

Once built, the plant will desalinate an annual 100 billion liters of water and convert it into potable and industrial process water for over 1.5 million people, thus meeting 20 percent of Israel’s water needs.

EagleBurgmann, a Freudenberg and EKK Group company, is supporting the project with sustainable sealing solutions, or – to be more specific – state-of-the art mechanical seals specially developed for extremely high pressures in water applications. Not only do they allow for a reliable and smooth operation but, thanks to their durability, they also help make the desalination plant more sustainable.

A reverse osmosis process is used to purify the water. This physical process to remove substances dissolved in liquids uses pressure to reverse the natural osmosis process.

The new plant will be the largest and most advanced desalination plant in the world. And when it comes to saving energy and preventing pollution, it is a true game-changer.

EagleBurgmann is supplying seals for the world’s largest seawater desalination plant.

- Expanding customers’ handprints

![]()

- Water

- Water pollution

- Water use

Examples of successful sustainability projects

Back to Sustainability