Eco-friendly solutions for a better world

How we make life more sustainable

At Freudenberg, we are dedicated to pioneering sustainable solutions that enhance everyday life. Our innovative approaches in renewable energy, waste reduction, and eco-friendly products are designed to help our customers become more eco-conscious and create a greener future for all.

Sealing the Future: How Materials Drive Hydrogen Technology

Freudenberg has invested heavily in developing technical materials over the years. This expertise is now unlocking the potential of hydrogen for the energy transition, with specially developed sealing materials playing a crucial role. Materials for the hydrogen economy must meet extremely stringent requirements. The problem is that hydrogen is the smallest chemical element; the diameter of a hydrogen molecule is just 0.07 nanometers, or less than a billionth of a meter. In its normal gaseous state, it can penetrate the tiniest openings. So ambitious plans for hydrogen as a fuel or storage medium begin and end with reliable sealing.

It takes deep material expertise to deal with the ephemeral gas. This is where Freudenberg Sealing Technologies, one of the company’s Business Groups, comes in. “The permeation has to be minimized, more to make systems safe and less due to losses in efficiency. If the hydrogen reaches the ambient air, the mixture with oxygen could quickly explode,” says Dr. Alexander Hähnel, a chemist. He is a member of the Technology & Innovation team working on hydrogen applications at Freudenberg Sealing Technologies.

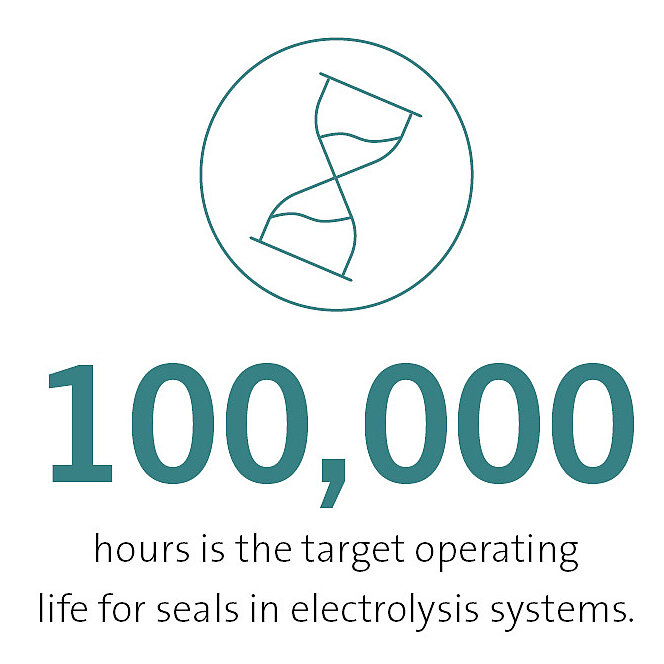

Facility operators are also insisting on tremendously long operating lives for seals. For example, an electrolysis system is expected to run nonstop for at least 10 years. That’s why their seals are designed for a lifespan of 100,000 hours. If a sealing material must maintain its full function over the entire lifespan, it cannot be allowed to age prematurely. It is not the hydrogen that attacks a seal’s rubber material. It is the side effects. In many cases, they result from high – and highly variable – pressures interacting with major temperature fluctuations.

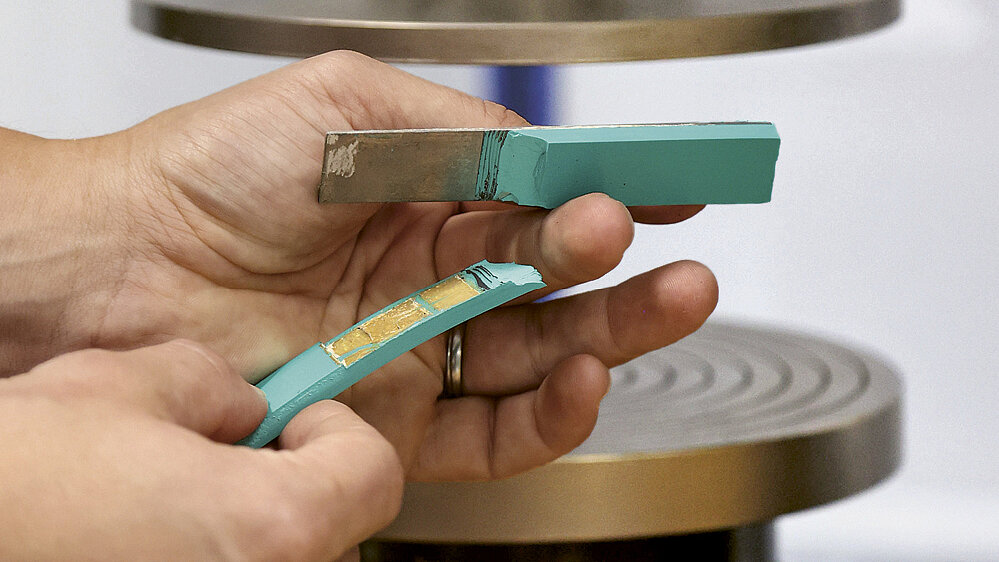

For example, when hydrogen tanks are filled up, explosive decompression can result if pressures change very quickly. Gas bubbles explode in the sealing material as they do in the blood of a diver ascending too quickly from deep water. Fine cracks are the result, along with an irreversibly damaged material structure. Other chemical effects cause the seal’s rubber compound to age. One example is oxidation from the oxygen in an electrolysis system. At a system pressure of 35 bar, the oxygen content is 175 times greater than the level in ambient air. The impact: Extremely aggressive oxidation acts on the material and greatly accelerates the aging process. High temperatures intensify the effect.

A material’s selection is based on pressure, temperature and duration of operation

“The material is the key to the seals’ optimal performance and the perfect operation of any system,” says Jürgen Emig, Director Pre-Product Development at Freudenberg Sealing Technologies. “We develop components specifically for a particular application. Our strength: The company recommends the optimal design to the customer based on the best-possible materials in close coordination with the requirements profile. The seals deliver the desired performance over the entire required lifespan.” Experts from various disciplines pull together – true to the company’s guiding concept of “Innovating Together.” The seals can also be combined with various other components to form a single part. Some examples are bipolar plates, thermoplastic films, and gas diffusion layers.

The material is the key to the seals’ optimal performance and the perfect operation of any system.

Jürgen Emig

Director Pre-Product Development at Freudenberg Sealing Technologies

The development of specialized materials plays a crucial role in the future of the hydrogen economy. Materials must not only ensure maximum sealing performance but also withstand extreme temperatures, pressure fluctuations, and chemical influences. Innovative material solutions help maximize the efficiency and safety of fuel cells and electrolysis systems. Research and continuous material optimization are therefore essential building blocks for the sustainable and economical use of hydrogen in industrial applications.

Investment in sophisticated test facilities

Freudenberg Sealing Technologies’ expertise involves more than just materials, design, and production processes. Wide-ranging lab research and component testing are essential components of its development process. Does a newly developed material meet the objectives set for it? Older testing technologies are reaching their limits considering the more demanding requirements. “We want to know in greater detail what happens under operating conditions so we can do our development work even closer to real-life applications,” Dr. Hähnel says. “Depending on the result, we are adjusting recipes and processes, pushing the limits of what is feasible.” All the tests make material qualities comprehensible to customers and allow operating life estimates for entire systems.

Freudenberg Sealing Technologies is now investing in other test equipment that will play to its strengths, especially in hydrogen applications. Some examples are new test stands to measure impermeability with higher precision and a greater range of pressures. Experts can gauge the impact of higher oxygen concentrations on aging with targeted tests. Electrochemical test stands are also expanding horizons: “Properties are affected by the electrical current running in the technical processes of fuel cells and electrolyzers. Now we can apply electric current to materials on a targeted basis and examine the effects,” Emig says. Several research projects are also underway to explore material effects even more fully.

“This is the highest level of material development. The work is paying off. Our customers are purchasing considerable knowhow with every seal,” Dr. Hähnel says. “In exchange, they are mainly getting higher process reliability for their facility.”

Quenching the thirst: Freudenberg mechanical seals solving one of mankind’s major problems

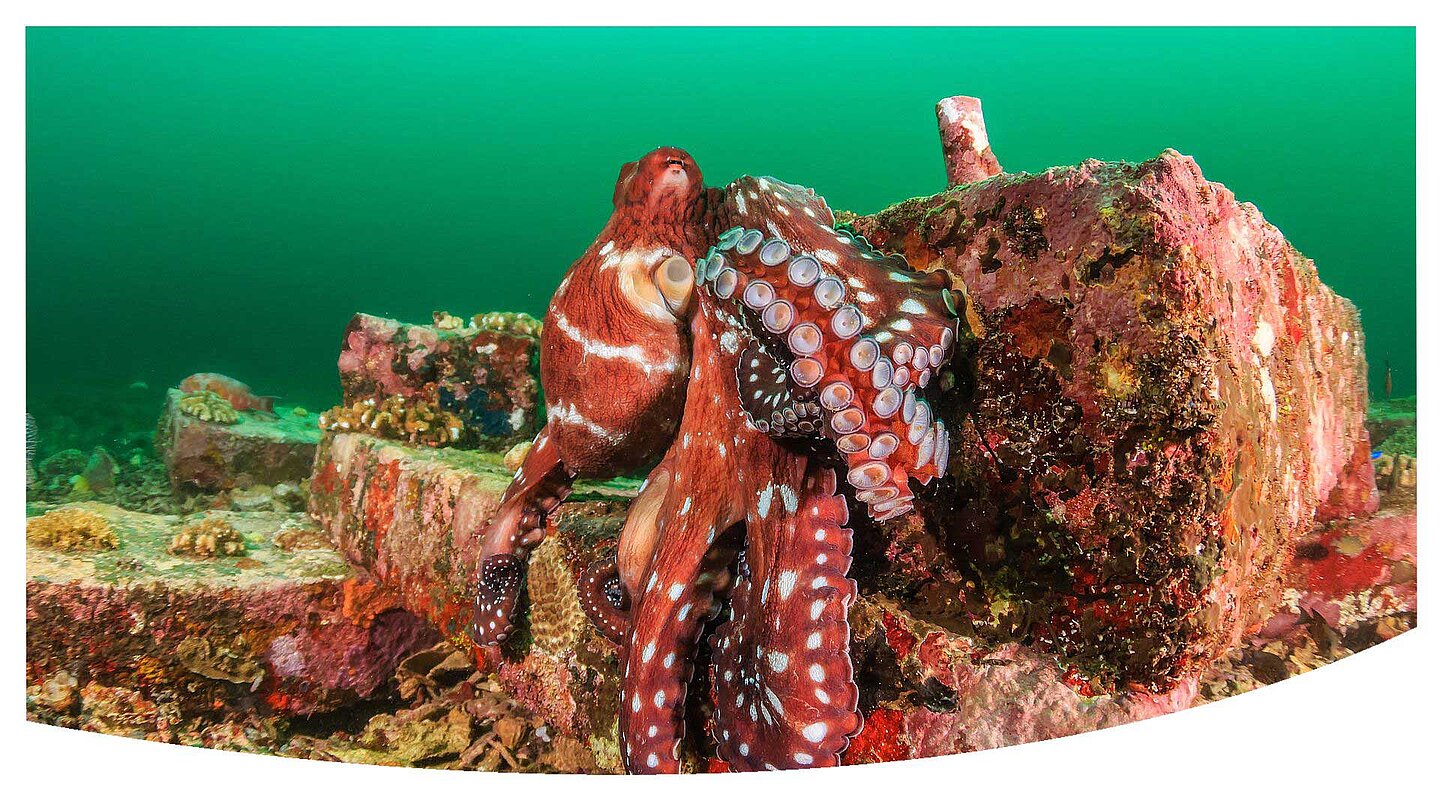

About 70% of our planet is ocean. EagleBurgmann, a Freudenberg company, has pioneered a technology that transforms sea water into a vital source of drinking water. Our sealing solutions help to quench the thirst of millions.

There is enough water – but only a fraction is drinkable

2.2 billion people do not get regular access to clean water.

Climate change is worsening the situation.

Water is desperately needed for human beings, but it’s also crucial for growing crops. Many of the drier areas have coastlines, but until recently the desalination of ocean water was expensive and did not provide enough safe, drinkable water.

Now, there is an improved process, and desalinated water has become a major source of drinking water for many regions of the world – thanks to modern sealing solutions from EagleBurgmann.

Our seals might be a comparatively small item in the production but for millions of people they make a significant difference.

EagleBurgmann is a sealing solution provider for all water applications:

- Industrial production

- Desalination

- Water industry

- Sealing technology for baths, thermal pools, spas and water parks

- Transportation and special real estate

The key to a greener future? More green.

As cities continue to grow rapidly, they require innovative concepts to balance the demand for more residential space with the need to preserve our environment on a global scale. Nonwovens by Freudenberg Performance Materials provide a surprisingly easy and effective solution for greener cities by creating vertical green spaces.

Greening the roofs and facades of buildings: Freudenberg Performance Materials green roof systems allow plants to grow while protecting the buildings.

Multiplying the greenspace in only clean the air and convert CO2 to oxygen, but the vegetation also insulates the buildings, thuslowering their carbon emissions. Less energy is needed to heat or cool the buildings to a comfortable temperature. Also, the nonwovens used in the green roof system are made from recycled PET bottles, thus reducing waste and carbon emissions.

Our products for green roof systems are making a difference.

Harnessing the potential of offshore wind responsibly

Offshore wind-turbines promise endless sustainable energy. But to wield it, the wind turbines must work hard under the toughest conditions.

With biodegradable lubricants from Klüber Lubrication, a brand of Freudenberg, we are protecting important machine parts and contributing to preserving the sensitive marine ecosystems for generations to come.

Protecting wildlife and material under the roughest conditions

Lubrication ensures the mechanics run smoothly and protects materials from the aggressive salt water. This increases the lifespan of machine parts and boosts energy yield by reducing friction. However, the open sea is also a sensitive eco-system that needs protection.

Biodegradable high-performance lubricants by Klüber Lubrication help to reduce the risk for maritime wildlife in case of any leakage. This makes them vital in securing performance and protecting the environment.

Certified sustainability: Klüber Lubrication is among the 2 % of the most sustainable companies.

Freudenberg combines the skills needed to pave the way for sustainable energy

Freudenberg Sealing Technologies develops unique material and product solutions to drive new energy applications like wind turbines, solar and hydroelectric plants, fuel cells, electrolyzers and switch gears to make energy more sustainable.

Climate change is compelling us to rethink how we create and store energy. As interest in decentralized systems increases, we are offering solutions to ensure these technologies operate effectively.

Offshore wind turbines work under some of the toughest environmental conditions. Our custom-engineered sealing solutions allow this technology to operate efficiently, reducing downtime.

Another focus of our innovative approach to sealing solutions drives the development of electrolyzers for the generation of hydrogen: new sealing solutions are needed for automated manufacturing which will grant a long lifetime in harsh environments.

With more than 175 years of history, Freudenberg contributes to improving functional reliability, operating lifespans, and environmental protection throughout the energy industry. Our seals are essential to the development of new energy.

Vileda: Smarter cleaning solutions with a clean consciousness

There is more to the cleaning solutions by Vileda than meets the eye: the ergonomic and convenient design and the outstanding cleaning performance. But let’s look at all the sustainable ideas behind efficient cleaning. Our products and packaging strive to meet high standards of sustainability – by being durable, recycled or recyclable.

Sustainability begins at home

Cleanliness often comes at an environmental cost, particularly with the use of harsh detergents and single use wipes. At Vileda, we work closely with our customers to develop high quality products that fulfill their needs. Not only do we give them the most ergonomic and efficient cleaning experience possible, but we also address their wish for more sustainable solutions. This allows our customers to enjoy a clean home and feel good about their environmental impact.

Vileda incorporates the innovative experience and expertise of the Freudenberg Group into everyday household items. The partnership between Vileda emphasizes Vileda’s commitment to creating a better world for future generations by providing customers with more sustainable solutions.