Sustainability

Our commitment to the future

At Freudenberg, sustainability plays a key role in everything we do. We are committed to preserving our planet for future generations. This means minimizing waste and emissions while reducing the use of water, energy, and materials to the absolute minimum. To achieve this, we continuously optimize our processes while developing sustainable products for our customers.

By 2045 at the latest, we aim to make our operations CO2-neutral—primarily by reducing energy consumption, embracing electrification, purchasing green electricity, and generating it ourselves. To achieve this goal, we are leveraging our manufacturing expertise and proven innovation capabilities.

The two dimensions of sustainability

In addition to our commitment to reducing our footprint, we offer numerous products and solutions that help our customers manufacture more efficiently and sustainably, or make their products more resource-efficient.

By minimizing our footprint and expanding the handprint of our customers, we actively contribute to a more sustainable world.

Freudenberg's energy consumption in 2024

Sustainability at Freudenberg:

Success stories from around the world

Optimized Compressed Air Management in Ireland Cuts Energy Consumption by 9%

At its facility in Carrick-on-Shannon, Ireland, Freudenberg Medical manufactures minimally invasive catheters in cleanroom environments. Compressed air is used to clean the products of fibers or particles.

Through a series of measures – including the implementation of a leak detection program, the installation of auto-off sensors that automatically interrupt airflow when not needed, and the use of pressure control valves – the energy efficiency has been significantly improved. The results are clear and impactful: Freudenberg Medical has reduced the annual energy consumption at the site by nearly 400 MWh, which represents a 9% decrease.

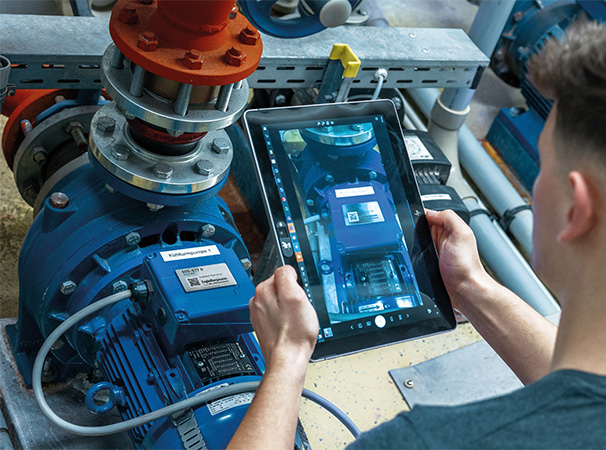

Digital Monitoring Extends Seal Lifespan

Seals play a crucial yet often unnoticed role. In applications like transcontinental pipelines, they can be difficult to access or located far from service teams. Freudenberg Flow Technologies' digital monitoring systems provide continuous oversight of sealing systems, allowing parameters such as pressure, temperature, and vibrations to be monitored remotely.

Battery-powered sensors are attached directly to the seal's inlets and outlets or even placed inside the seal itself. The collected data is transmitted wirelessly, monitored, and analyzed. If any values exceed predefined limits, an alarm is triggered, and the customer is notified. This proactive monitoring helps prevent subsequent damage, costly repairs, and excessive material and resource use. In extreme cases, this technology also safeguards against severe environmental and safety impacts.

14% Less Energy and 13% Less CO2 at our Wuxi Facility in China

In 2023, the Vibracoustic plant in Wuxi, China, conducted an energy efficiency analysis in collaboration with energy experts from Freudenberg Service KG. As part of the internal initiative "Be energy efficient", the goal was to analyze major sources of energy consumption such as dryers, motors, generators, and HVAC systems to identify potential savings.

Based on a detailed action plan, several measures were implemented to reduce energy consumption and CO2 emissions at the plant. Targeted actions, such as the introduction of a digital energy management system to monitor energy usage, optimizing machinery, and upgrading the compressed air system, led to the desired results: the plant achieved a 13% reduction in CO2 emissions and a 14% reduction in energy consumption!

Specialty Lubricants: A Simple and Cost-Effective Way to Reduce Energy Costs

Specialty lubricants offer an easy and cost-efficient way to lower energy costs. Klüber Lubrication, a brand of Freudenberg, supports its customers in identifying cost-saving opportunities with its "Klüber Energy Efficiency" program. The process begins with measuring energy consumption using the original lubricant, followed by an analysis of the results. Based on this, a tailored specialty lubricant is recommended for the specific application. Subsequent measurements are used to validate the improvements and energy savings.

An example of how this process is working to save costs and energy is Klüber Lubrication’s collaboration with Graham Packaging, a leading manufacturer of packaging products. At its plant in Belgium, optimized lubrication of the extruder gearboxes led to more than 2% in energy savings over the product’s lifetime and a CO₂ reduction of more than 11 tons—equivalent to the amount of carbon captured by approximately five trees over their entire lifespan.

A New Way of Welding: No Water, No Chemicals, and Far Less Energy

Freudenberg Sealing Technologies’ accumulator manufacturing facility in Remagen, Germany, sought a more sustainable method for welding diaphragm accumulators. To achieve a secure and durable weld, surfaces must be free of contaminants such as grease and oil. Until recently, that required a cleaning process that relied on wet-chemical industrial washing machines.

In early 2025, the facility switched to laser technology. This is expected to reduce electricity consumption by more than 90%, bringing significant cost savings. Additionally, this new method eliminates the need for process water and chemicals, while also limiting scrap and rework thanks to its enhanced cleaning performance. A step toward greater sustainability!

Plastics-Free Packaging? Yes, It’s Possible!

Strategic packaging designs are needed to protect the EasyWring Spin Mop and Bucket System and Easy Wring RinseClean Spin Mop System, from Freudenberg Home and Cleaning Solutions, as they travel to retail stores in the U.S. and Canada.

To eliminate plastic from the packaging of these products, we evaluated the production and logistics processes and found innovative solutions to ensure the mop heads remain clean and intact throughout transport while decreasing the materials needed to package these products.

The results are remarkable: 50,000 kilograms of packaging material are saved each year, reducing CO₂ emissions by 125,000 kilograms. A powerful example of how sustainability and economic efficiency work together.

Responsibility Report 2024

This Responsibility Report sets out our commitment to the environment and society.